The Manufacturing Process and Evolution of China’s Adjustable Claw Hammer

Introduction

China’s adjustable claw hammer is a versatile and essential tool in the construction industry. Its unique design and functionality have made it a popular choice among professionals and DIY enthusiasts alike. In this blog post, we will explore the manufacturing process of this hammer and delve into its origin and development over the years.

Manufacturing Process

The manufacturing process of China’s adjustable claw hammer involves several key steps and techniques. Let’s take a closer look at each of them:

Material Selection

The first step in manufacturing an adjustable claw hammer is selecting the appropriate materials. Typically, the head of the hammer is made from high-quality steel, known for its durability and strength. The handle is commonly crafted from wood or fibreglass, providing a comfortable grip and reducing vibration.

Forging the Head

Once the materials are chosen, the steel for the hammerhead undergoes a forging process. This involves heating the steel to a high temperature and shaping it using a drop hammer or a power hammer. The head is then cooled and tempered to enhance its hardness and toughness.

Shaping the Claw

The next step is shaping the claw of the hammer. This is done by cutting and grinding the steel to create the distinctive curved shape. The claw is carefully designed to provide maximum leverage for pulling out nails and other tasks.

Handle Preparation

Simultaneously, the handle is prepared by cutting the wood or fibreglass to the desired length. The handle is then shaped and sanded to ensure a smooth and comfortable grip. For wooden handles, they are often treated with a protective coating to enhance durability.

Assembly

In this step, the hammerhead and handle are joined together. The head is securely attached to the handle using a combination of adhesive and mechanical fasteners, such as screws or wedges. This ensures a strong and reliable connection.

Origin and Development

The adjustable claw hammer has a rich history in China. It originated from the traditional claw hammer, which had a fixed claw and limited functionality. As the demand for a more versatile tool grew, Chinese craftsmen began experimenting with adjustable designs.

Over time, the adjustable claw hammer evolved to incorporate innovative features. The ability to adjust the claw’s position allowed users to adapt the tool to different tasks, such as prying, splitting, and hammering. This versatility makes it a preferred choice for professionals and DIY enthusiasts worldwide.

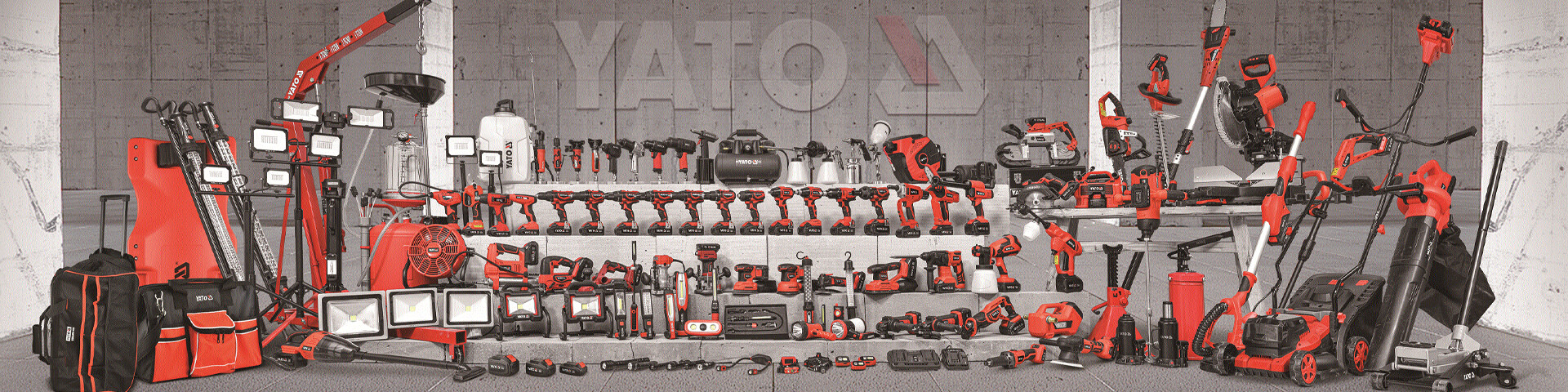

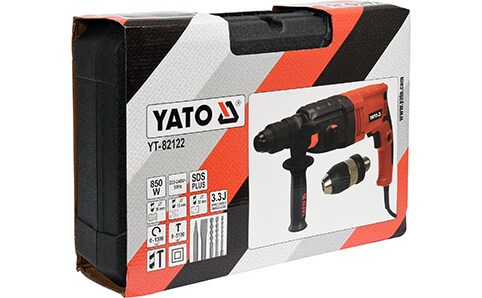

Recommendation: YATO and its Products

When it comes to high-quality adjustable claw hammers, one brand that stands out is YATO. Yato is a renowned manufacturer of hand tools, known for its commitment to excellence and innovation. Their adjustable claw hammers are crafted with precision and attention to detail, ensuring durability and optimal performance.

YATO’s adjustable claw hammers from China feature ergonomic handles for a comfortable grip, and their heads are made from premium steel, providing exceptional strength and durability. Whether you are a professional tradesperson or a DIY enthusiast, YATO’s adjustable claw hammers are a reliable choice for all your hammering needs.