Electric Cut Off Machine Manufacturers: A Complete Guide

Electric cut-off machines have become indispensable tools in various industries, enabling precise and efficient cutting of metal, wood, and other materials. This guide dives deep into the world of electric cut off machine manufacturers, exploring their significance, offerings, and why they are essential in today’s industrial landscape.

What Is an Electric Cut Off Machine?

An electric cut-off machine, often referred to as a chop saw or cut-off saw, is a power tool designed for heavy-duty cutting tasks. It uses an abrasive disc or diamond blade to cut through hard materials with precision. These machines are particularly favored in construction, manufacturing, and metalworking due to their efficiency and accuracy.

Key Features of Electric Cut Off Machines

- Powerful Motor: Ensures seamless cutting of tough materials.

- Adjustable Angles: Facilitates versatile cutting operations.

- Safety Mechanisms: Includes spark deflectors and blade guards for user protection.

- Durable Build: Designed for long-term use in demanding environments.

Why Choose a Reliable Electric Cut Off Machine Manufacturer?

The quality and efficiency of your cutting operations depend heavily on the manufacturer of the machine. Top electric cut off machine manufacturers prioritize innovation, safety, and reliability, ensuring their machines meet industrial standards.

Benefits of Choosing Established Electric Cut Off Machine Manufacturers:

● Superior Build Quality: Reliable manufacturers use high-grade materials to enhance machine durability.

● Innovative Technology: Leading companies integrate advanced features like dust collection systems and variable speed controls.

● Comprehensive Support: From warranties to customer service, established manufacturers ensure a seamless experience.

Top Applications of Electric Cut Off Machines

Electric cut-off machines serve a variety of industries, including:

- Metalworking: Cutting pipes, sheets, and bars.

- Construction: Precision cutting of tiles, bricks, and concrete.

- Woodworking: Used in specific applications where fine woodcuts are required.

- Automotive: Essential for cutting exhaust pipes, panels, and more.

Chinese Electric Cut Off Machine Factory: A Growing Force

In recent years, China has emerged as a global hub for manufacturing electric cut-off machines. A Chinese electric cut off machine factory often combines affordability with cutting-edge technology, making it a preferred choice for buyers worldwide.

Why Consider Chinese Manufacturers?

- Competitive Pricing: Chinese factories offer high-quality machines at lower costs due to efficient production techniques.

- Customization: Many factories provide tailored solutions to meet specific industrial requirements.

- Global Reach: With robust export networks, Chinese manufacturers cater to a global clientele.

How to Select the Right Electric Cut Off Machine Manufacturer

Choosing the right manufacturer is crucial for maximizing your investment. Here are some factors to consider:

1. Reputation

Look for manufacturers with a proven track record of delivering reliable and high-performing machines. Customer reviews and industry certifications are good indicators.

2. Product Range

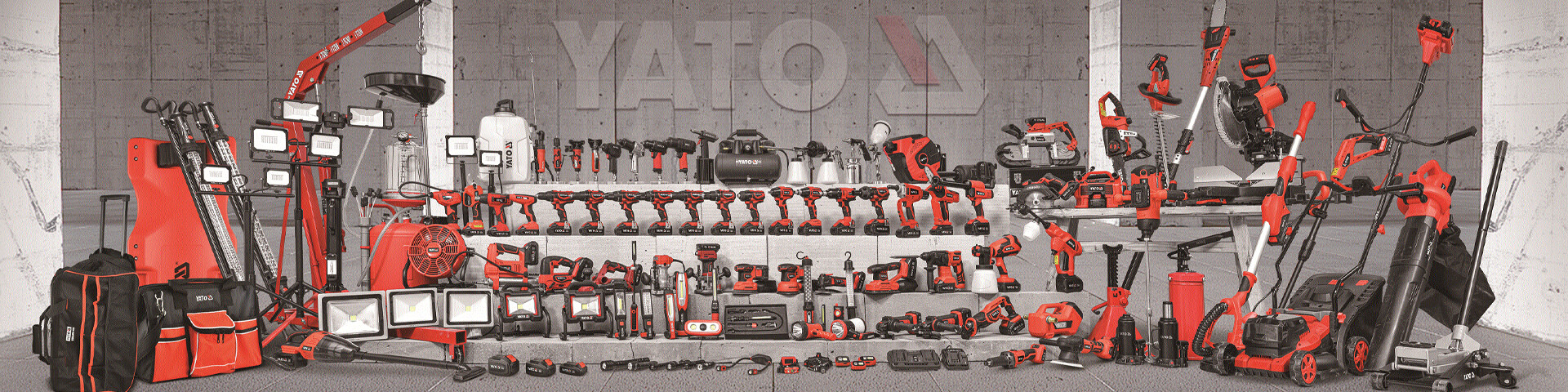

Ensure the manufacturer offers a diverse range of models, catering to different industrial needs.

3. After-Sales Support

Comprehensive warranties, maintenance services, and technical support are essential.

4. Compliance with Standards

Machines should adhere to international safety and performance standards.

Leading Electric Cut Off Machine Manufacturers

Several global and regional manufacturers have established themselves as leaders in this domain. While Western brands focus on premium features, the cut off machine factories have gained traction for their innovation and cost-efficiency.

Example Brands to Explore:

● European Manufacturers: Known for advanced technology and robust builds.

● Chinese Manufacturers: Offer competitive pricing and global shipping options.

● Local Specialists: Provide region-specific solutions tailored to niche industries.

Future Trends in Electric Cut Off Machines

The electric cut-off machine industry is evolving rapidly, with manufacturers embracing new technologies to enhance performance and sustainability.

Key Trends:

- Eco-Friendly Solutions: Manufacturers are focusing on reducing energy consumption and emissions.

- Smart Features: Integration of IoT for monitoring machine performance in real time.

- Enhanced Safety: Advanced sensors to prevent accidents during operation.

Final Thoughts

Selecting the right electric cut off machine manufacturers can significantly impact your operational efficiency and costs. Whether you opt for a renowned global brand or a factory, the key lies in understanding your specific requirements and aligning them with the manufacturer’s offerings.

By focusing on quality, innovation, and customer support, manufacturers continue to play a pivotal role in driving industrial progress worldwide.