Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

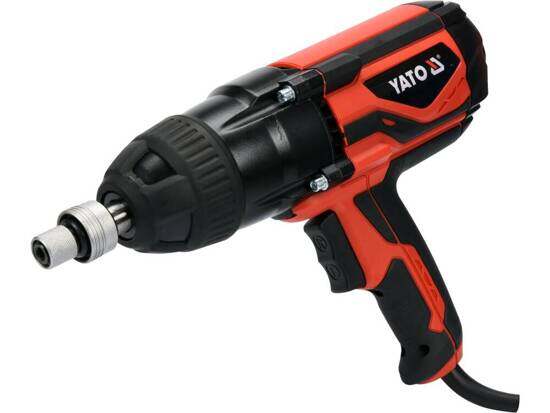

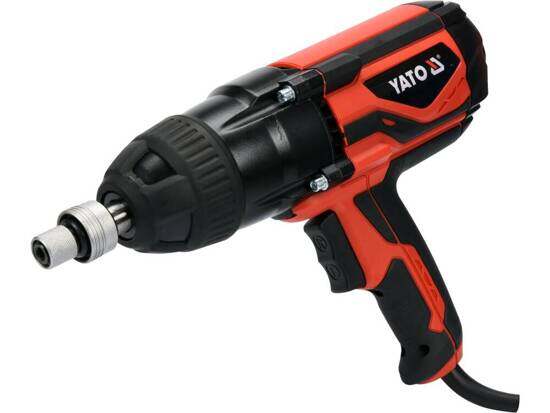

An electric impact wrench is a powerful tool that uses electricity to generate rotational force, which is then applied to loosen or tighten nuts and bolts with ease. It is commonly used in automotive repair and construction industries, offering efficiency and convenience compared to traditional manual wrenches.