Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

A hydraulic bottle jack is a compact lifting device that uses hydraulic pressure to raise heavy loads. It consists of a cylindrical body filled with hydraulic fluid and a piston that moves up and down. When the handle is pumped, fluid is forced into the cylinder, lifting the piston and raising the object placed on top of the jack. Known for its strength and ease of use, the bottle jack is commonly used in automotive repair, construction, and other applications where heavy lifting is required. Its portability makes it a popular choice for both professional mechanics and DIY enthusiasts.

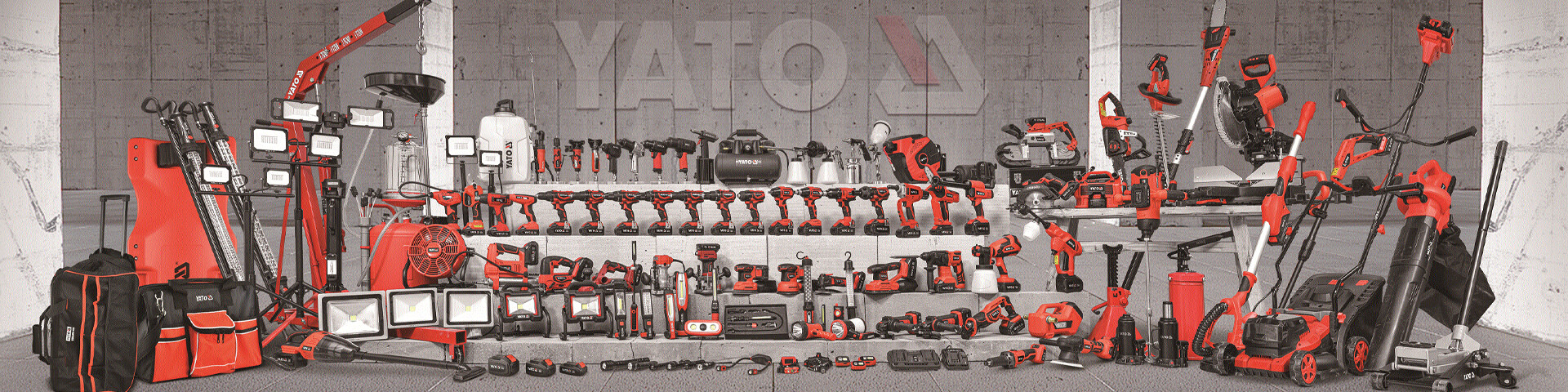

Hydraulic Bottle Jack

The Features

Application Area